Rubber Piping

Rubber piping expansion joints, also known as rubber expansion joints or rubber bellows, are flexible connectors used in piping systems to absorb movement, vibration, and thermal expansion while maintaining a seal and integrity of the system. These joints are typically made of elastomeric materials such as natural rubber, EPDM (Ethylene Propylene Diene Monomer), neoprene, or nitrile rubber.

They are designed to compensate for misalignment, reduce noise and vibration transmission, and prevent damage to piping and equipment due to thermal expansion or contraction. Rubber expansion joints are commonly used in various industries, including HVAC (heating, ventilation, and air conditioning), water treatment, power generation, and chemical processing.

Arches play a pivotal role in the performance of an expansion joint, serving as its backbone. It determines the joint's range of movement and dictates the types of media it can accommodate. The design of the arch is crucial in ensuring the joint's flexibility, durability, and ability to absorb movements and vibrations.

Rubber piping expansion joint arch types:

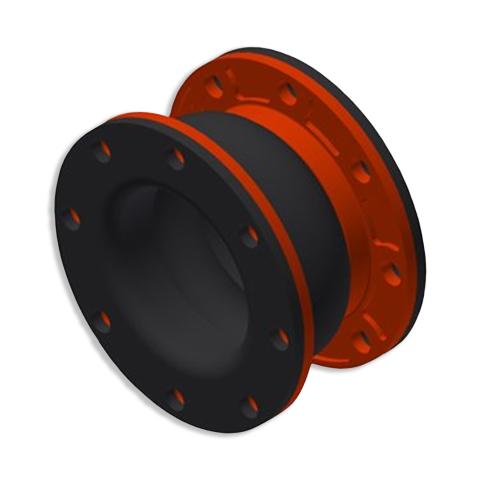

Single Arch: Consists of a single arched section engineered to absorb movement in one direction. Their design allows for axial, lateral, and angular movements, all while maintaining a tight seal between connecting pipes. We commonly use single arch expansion joints where moderate movement is required such as in heating, ventilation, air conditioning (HVAC), and plumbing systems.

Single Wide Arch: Consists of a wider arch section compared to standard arches, providing enhanced flexibility and movement absorption. Typically, we use single wide arch expansion joints for larger industrial pipelines, power plants, and chemical processing facilities where longer spans and greater movement capacities are necessary.

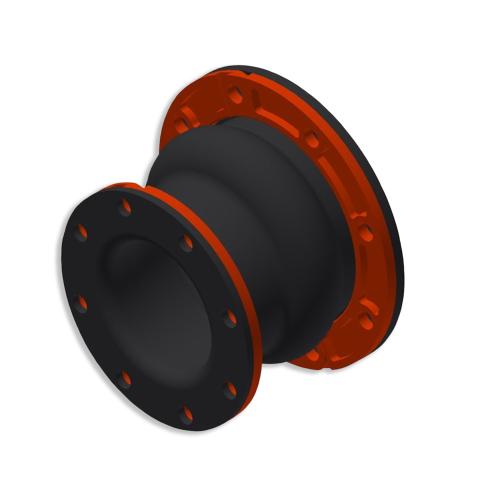

Double Arch: Features two arched sections within its structure, allowing for increased movement capability in the piping system compared to single arch joints. This design effectively reduces the spring rate of the joint, meaning it can absorb movements more smoothly and with less resistance compared to single arch joints. Typically, we prefer to use double arch joints in more complex piping configurations where there is a need for greater flexibility and movement capacity, knowing that they are suitable for environments with significant temperature variations.

Triple Arch: Features three arched sections within its structure, offering enhanced movement capability compared to single or double arch joints. This design is particularly effective in accommodating large amounts of thermal expansion and contraction in piping systems. We commonly use triple arch expansion joints in applications where extensive flexibility and movement capacity are required, especially in environments with significant temperature variations and complex piping configurations.

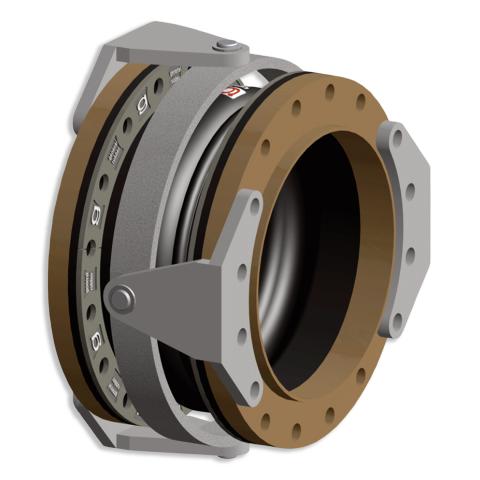

Filled Arch: Refers to a type of expansion joint where the arch cavity is filled with a material to enhance its performance characteristics. The filling material typically serves to support the structure, provide additional resistance to pressure, or improve the joint's ability to handle specific media or environments. These joints are designed with the same basic structure as traditional arch expansion joints, however, instead of having an empty cavity within the arch, it is filled with material such as foam, fabric, or other elastomers. This filling helps to stabilize the joint, improve its resistance to high pressures, and reduce turbulence within the flow path. We typically chose filled arch expansion joints for applications where there is a need for enhanced durability, increased resistance to abrasion or corrosion, or specific requirements for media compatibility.